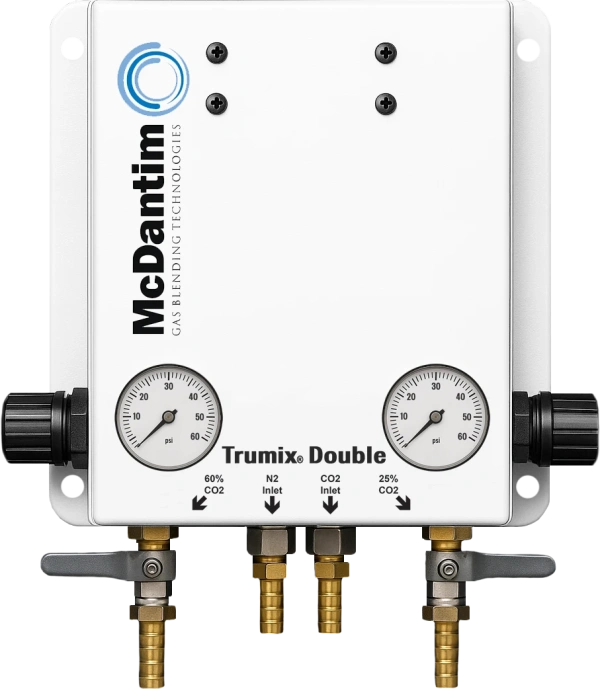

Mixed Gas Blenders for Draft Beer Systems

Mixed gas blenders let you create the perfect balance of CO₂ and nitrogen for every beer you serve. Instead of relying on pre-mixed cylinders, a gas blender draws from separate CO₂ and nitrogen sources and delivers a consistent custom blend directly to your beverage lines.

Want to explore your options? We're here to help.

Talk to UsSupport & Services

-

InstallationLearn More

-

MaintenanceLearn More

-

LeasingLearn More

For bars, breweries, and restaurants with multiple beer styles on tap, a mixed gas blender provides unmatched control and flexibility. Dial in the right carbonation and mouthfeel for stouts, ales, lagers, and more — all from a single system installed on-site.

Why Use a Mixed Gas Blender?

- Perfect CO₂ and nitrogen ratios for every beverage

- Eliminates reliance on pre-mixed gas deliveries

- Ideal for breweries, brewpubs, and multi-tap locations

- Lower long-term operating costs

- Better consistency and pour quality

Advantages of Beer Gas Blenders

| Mixed Gas Blender System | Pre-Mixed Beer Gas Cylinders |

|---|---|

| Custom CO₂ and nitrogen ratios on-site | Fixed gas mix only |

| Continuous supply without swapping cylinders | Requires constant cylinder exchanges |

| Lower cost over time | Ongoing rental and refill fees |

| Perfect for high-volume, multi-tap setups | Better suited for low-volume use |

| Consistent pressure and carbonation quality | Pressure can vary as cylinders empty |

Pair With a Nitrogen Generator for Complete Control

When combined with an on-site Nitrogen Generator, a mixed gas blender gives you a complete, self-sufficient beverage gas system. Generate your own nitrogen, blend it with CO₂, and control your beer gas mix without waiting on cylinder exchanges or deliveries.

Not sure which blend ratios are best for your taps? Visit our Beer Gas information page for a full breakdown of beer styles and gas mix recommendations.